In the world of industrial fluid handling, progressive cavity pumps have earned a reputation for their reliability and versatility. At the heart of this efficiency are the progressive cavity pump parts that contribute to their superior performance. Investing in high-quality parts is not just a matter of preference; it is a strategic decision that can lead to significant benefits for any operation. In this article, we will explore the compelling reasons to invest in progressive cavity pump parts.

Understanding Progressive Cavity Pumps

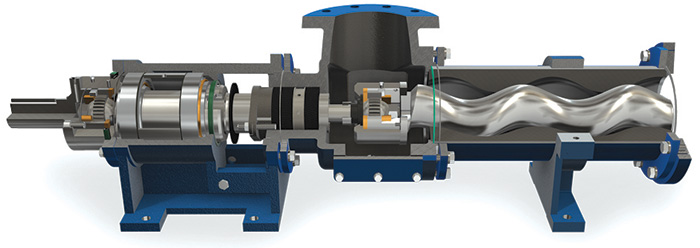

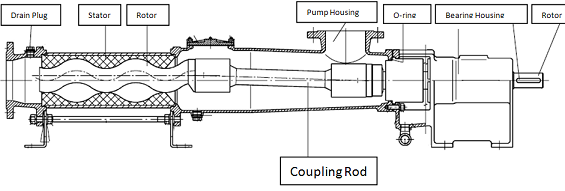

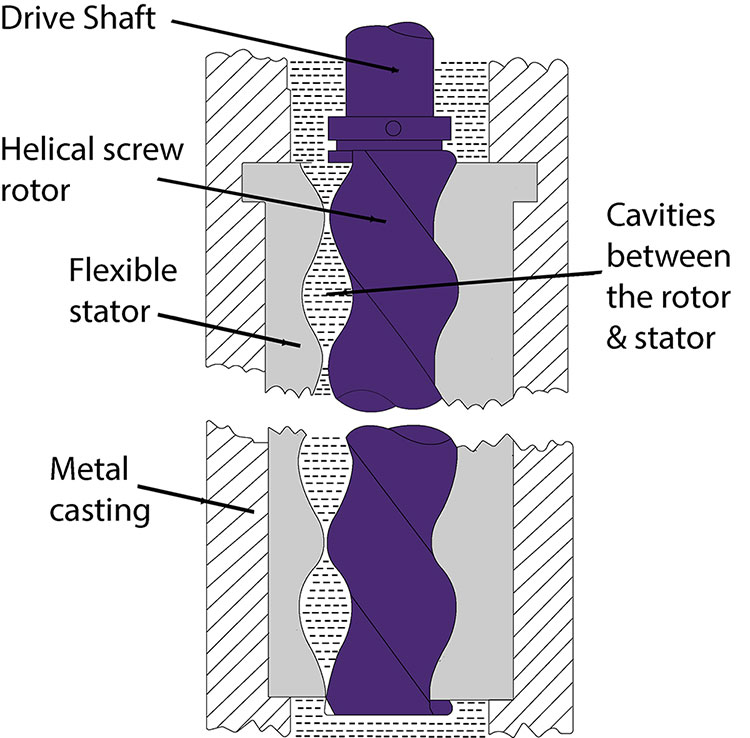

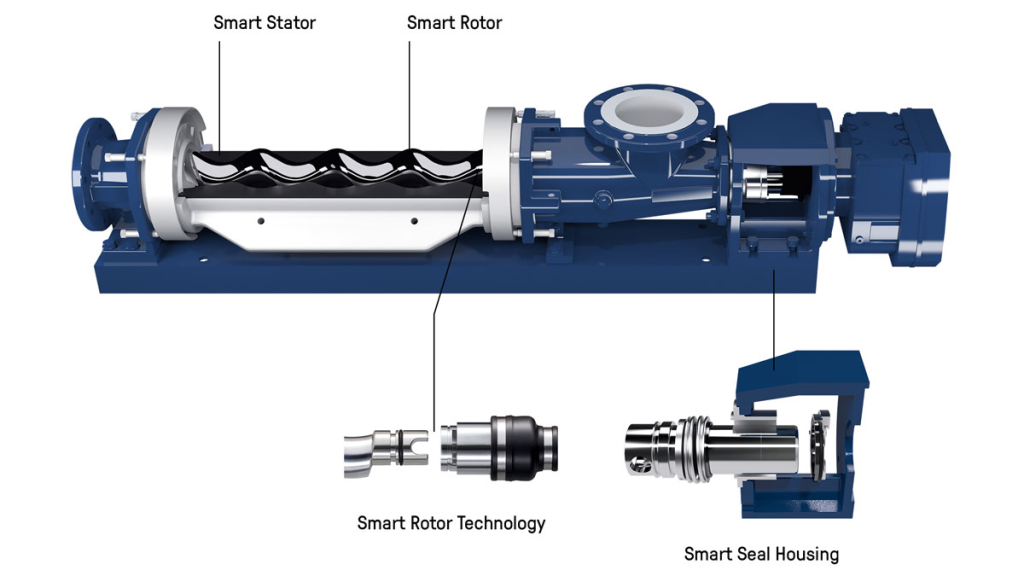

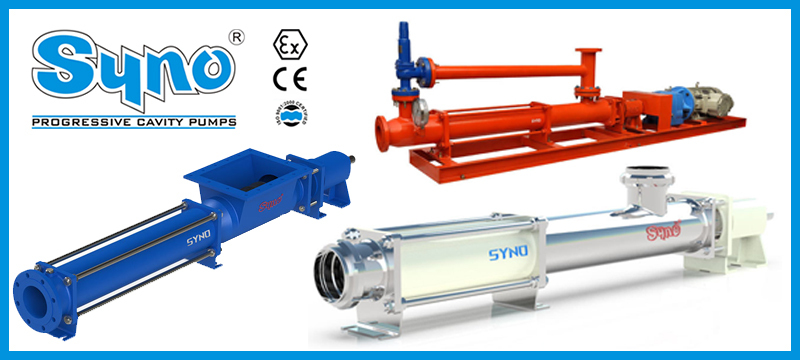

Progressive cavity pumps are designed to move fluids through a series of cavities created by a helical rotor and a stator. This unique design allows them to handle a wide range of fluids, including viscous and abrasive materials. The effectiveness of these pumps relies heavily on the quality of their components, which work together to ensure consistent and reliable operation.

The Importance of Quality Parts

Enhanced Performance

The performance of a progressive cavity pump is largely determined by its individual parts. High-quality components, such as rotors and stators, create a tighter seal and smoother operation. This leads to improved flow rates and reduced energy consumption. When each part functions optimally, the entire system operates at peak efficiency, making it a wise investment for any business.

Increased Reliability

Reliability is a critical factor in industrial operations. Downtime can lead to lost revenue and disrupted workflows. By investing in quality progressive cavity pump parts, businesses can minimize the risk of failures and breakdowns. Durable components reduce the likelihood of unexpected maintenance, allowing operations to run smoothly and efficiently.

Extended Lifespan

One of the most significant advantages of investing in high-quality parts is the extended lifespan of the pump. Quality materials and precision engineering reduce wear and tear, resulting in a longer operational life. This longevity not only saves money on replacements but also enhances the overall return on investment. A pump that lasts longer means fewer disruptions and a more consistent production process.

Versatility in Application

Adaptability to Various Fluids

Progressive cavity pumps are known for their versatility. They can handle a wide array of fluids, including those that are thick, abrasive, or contain solids. The ability to customize pump parts allows these systems to be tailored to specific applications, ensuring optimal performance across different industries. This adaptability makes them an invaluable asset in sectors such as oil and gas, food processing, and wastewater treatment.

Efficient Handling of Challenging Materials

Many industries face the challenge of moving difficult materials. Progressive cavity pump parts are engineered to handle these challenges efficiently. Whether dealing with slurries, emulsions, or other complex mixtures, the right components ensure that the pump functions effectively, reducing the risk of clogs or other operational issues. Investing in quality parts means having the confidence to tackle even the most demanding applications.

Cost-Effectiveness in the Long Run

Reduced Maintenance Costs

While the initial investment in high-quality progressive cavity pump parts may seem higher, the long-term savings can be substantial. Reliable components lead to fewer breakdowns and less frequent maintenance, significantly lowering overall maintenance costs. This financial benefit becomes particularly evident over time, making quality parts a cost-effective choice.

Enhanced Energy Efficiency

Quality parts contribute to the energy efficiency of progressive cavity pumps. When components are designed to work seamlessly together, the pump operates more efficiently, consuming less energy to achieve the same output. This not only lowers operational costs but also supports sustainability initiatives by reducing the carbon footprint of industrial processes.

Improved Safety and Compliance

Minimizing Risks

Safety is paramount in any industrial setting. High-quality progressive cavity pump parts are less likely to fail, which minimizes the risk of leaks and spills that can create hazardous situations. Investing in reliable components contributes to a safer working environment, protecting employees and reducing the likelihood of regulatory violations.

Meeting Industry Standards

Many industries are subject to strict regulations regarding equipment performance and safety. By using high-quality parts, companies can ensure that their pumps meet or exceed these standards. Compliance not only avoids potential fines but also enhances the company’s reputation as a responsible and reliable operator.

Conclusion

Investing in progressive cavity pump parts is a decision that can yield substantial benefits for any industrial operation. From enhanced performance and increased reliability to extended lifespan and cost-effectiveness, the advantages are clear. By prioritizing quality, businesses can optimize their fluid handling processes, reduce maintenance needs, and create a safer working environment. Ultimately, the investment in high-quality progressive cavity pump parts is not just a choice; it is a strategic move towards greater efficiency, productivity, and success in today’s competitive landscape.