The choice of pumps in industrial applications can significantly impact efficiency, maintenance costs, and overall operational effectiveness. Among various pumping solutions, progressive cavity pumps have gained recognition for their unique capabilities. This article explores whether investing in progressive cavity pumps manufacturers is worthwhile, examining their advantages, applications, and considerations.

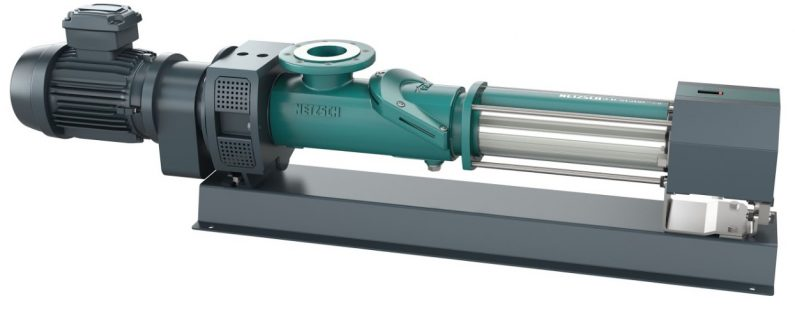

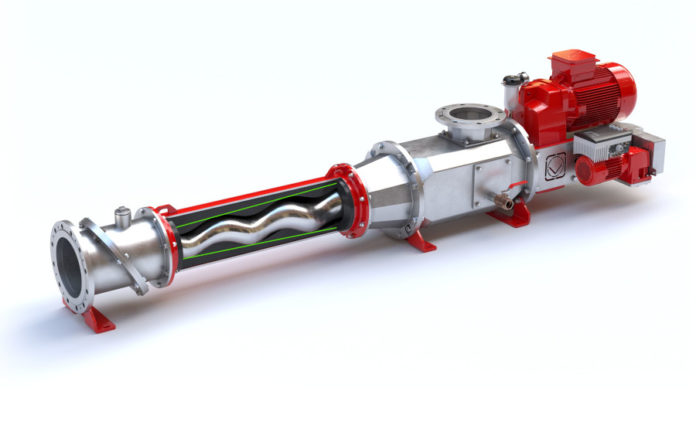

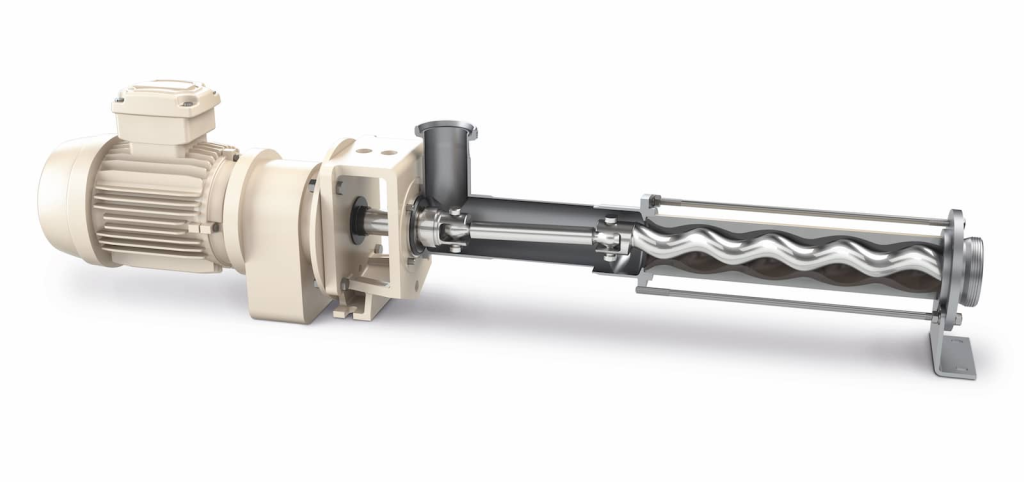

Understanding Progressive Cavity Pumps

Progressive cavity pumps, often referred to as PC pumps, are positive displacement pumps designed to handle viscous fluids and slurries. They consist of a helical rotor that rotates within a stator, creating a series of cavities that transport fluids. This design allows for a smooth and continuous flow, making them suitable for various applications.

Key Features of Progressive Cavity Pumps

- Versatility

Progressive cavity pumps can handle a wide range of fluids, including those with high viscosity, abrasive substances, and shear-sensitive materials. This versatility makes them suitable for industries such as food and beverage, wastewater treatment, and chemical processing. - Consistent Flow Rate

The design of PC pumps allows for a steady flow rate, even under varying pressure conditions. This consistency is crucial for processes that require precise fluid control. - Low Shear

These pumps operate with low shear, making them ideal for transporting delicate materials that cannot withstand high turbulence. This feature is particularly beneficial in the food industry, where maintaining product integrity is essential.

Benefits of Investing in Progressive Cavity Pumps Manufacturers

Investing in reputable progressive cavity pumps manufacturers can yield multiple benefits for businesses. Here are some key advantages:

- Quality Assurance

Established manufacturers adhere to stringent quality standards, ensuring that their pumps are reliable and durable. This reduces the likelihood of breakdowns and maintenance issues. - Technical Support

Leading manufacturers provide comprehensive technical support and guidance, helping businesses select the right pumps for their specific needs. This support can be invaluable in optimizing pump performance.

- Innovation and Technology

Manufacturers often invest in research and development, leading to innovative designs and improved efficiency. By choosing a progressive cavity pump manufacturer that prioritizes innovation, companies can benefit from the latest advancements in pumping technology. - Customization Options

Many manufacturers offer customizable solutions tailored to unique operational requirements. This flexibility allows businesses to optimize their pumping systems for maximum efficiency.

Applications of Progressive Cavity Pumps

Understanding the diverse applications of progressive cavity pumps can help businesses appreciate their value. Key industries where these pumps are commonly used include:

- Food and Beverage

In this sector, PC pumps are used to transport products like sauces, creams, and pastes, ensuring quality and consistency. - Wastewater Treatment

Progressive cavity pumps are effective in handling sludge and other viscous materials, playing a crucial role in wastewater management. - Chemical Processing

The ability to handle corrosive and viscous fluids makes PC pumps essential in the chemical industry, where safety and efficiency are paramount.

Considerations Before Investing

While there are clear benefits to investing in progressive cavity pumps manufacturers, businesses should also consider several factors:

- Initial Cost vs. Long-Term Savings

While the initial investment may be higher compared to other pump types, the long-term savings from reduced maintenance and increased efficiency can offset these costs. - Specific Needs

Not all applications require progressive cavity pumps. Businesses must assess their specific pumping needs and determine whether PC pumps are the best fit. - Supplier Reliability

Choosing a reputable manufacturer is vital. Researching their track record and customer reviews can help ensure a wise investment.