How to Maximize the Benefits of Progressive Cavity Spare Parts

Roper pump progressive cavity spare parts are essential for maintaining the efficiency and longevity of your progressive cavity pumps. When replacing worn components, be sure to use high-quality, OEM-approved parts that are designed specifically for your pump model. This ensures a perfect fit and optimal performance. Additionally, keep a stock of common wear items like rotors, stators, and seals on hand so you can quickly service your pumps and minimize downtime. Regularly inspecting and maintaining your progressive cavity spare parts can help you maximize the benefits of this robust and reliable pumping technology, including extended service life, reduced maintenance costs, and consistent fluid handling performance.

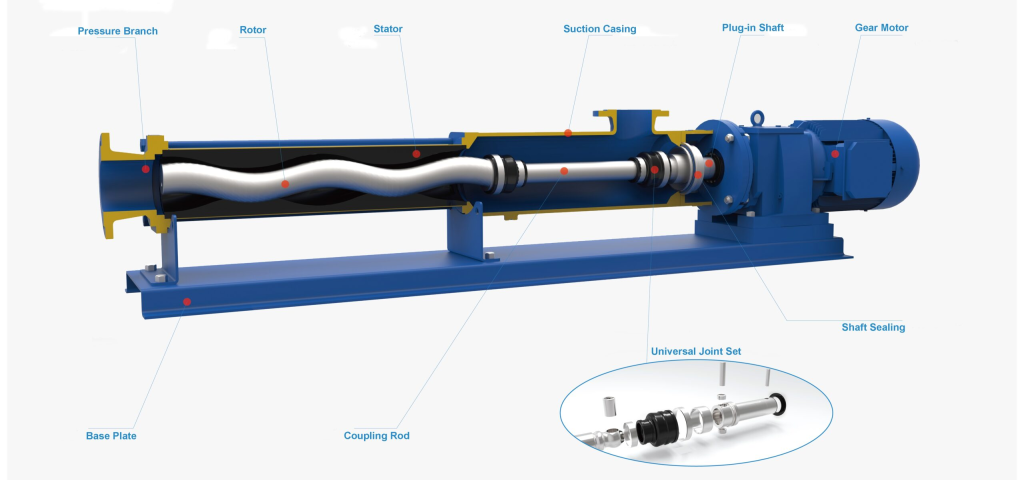

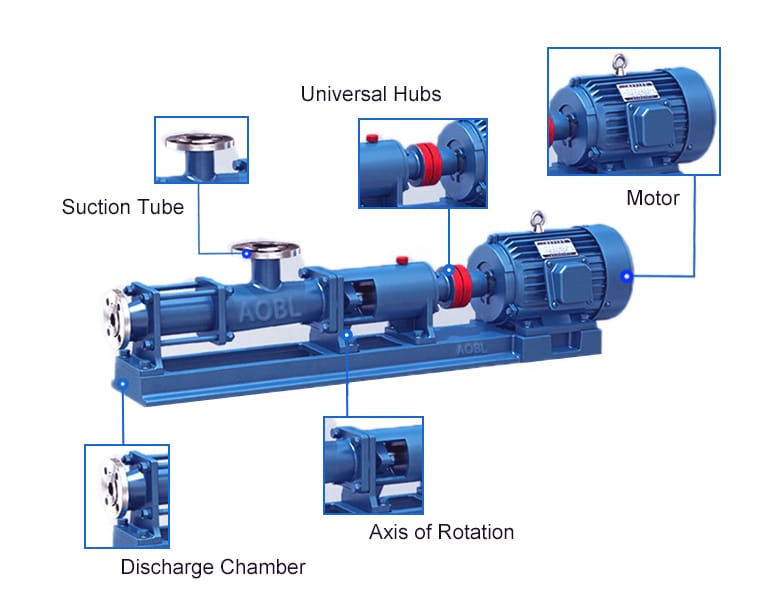

Understanding Progressive Cavity Pumps

Progressive cavity pumps consist of a helical rotor that turns within a specially designed stator. This unique design allows for a consistent and smooth flow of fluid. However, over time, wear and tear on these components can lead to decreased performance. Here’s how to optimize the use of spare parts.

1. Choose High-Quality Spare Parts

- OEM vs. Aftermarket: Always prioritize Original Equipment Manufacturer (OEM) parts over aftermarket options. OEM parts are designed specifically for your pump model, ensuring compatibility and reliability.

- Material Selection: Opt for parts made from durable materials that can withstand the specific conditions of the fluids being pumped, such as temperature and viscosity.

2. Regular Maintenance and Inspection

- Scheduled Maintenance: Establish a regular maintenance schedule to inspect and replace spare parts as needed. This proactive approach can prevent unexpected breakdowns.

- Visual Inspections: Regularly check for signs of wear, such as cracks or deformations in the rotor and stator. Early detection can save costs in the long run.

3. Optimize Pump Operation Conditions

- Fluid Characteristics: Ensure that the fluids being pumped are within the operational limits of the pump. Excessively viscous or abrasive fluids can accelerate wear.

- Proper Priming: Make sure the pump is properly primed to avoid air pockets that can lead to cavitation and damage.

4. Train Your Staff

- Proper Training: Ensure that operators are well-trained in the operation and maintenance of progressive cavity pumps. Understanding how to correctly use and maintain the equipment can significantly enhance its lifespan.

- Troubleshooting Skills: Equip staff with troubleshooting skills to quickly identify and resolve issues, minimizing downtime.

5. Monitor Performance Metrics

- Flow Rate and Pressure: Regularly monitor the flow rate and pressure to detect any deviations from normal operating conditions. Anomalies can indicate wear or impending failure of spare parts.

- Power Consumption: Keep an eye on the power consumption of the pump. A sudden increase can signal that spare parts may need to be replaced.

6. Implement a Spare Parts Inventory System

- Stock Essential Parts: Maintain an inventory of critical spare parts to reduce downtime in case of failures. Regularly review the inventory to ensure that the most commonly used parts are in stock.

- Supplier Relationships: Build strong relationships with reliable suppliers to ensure quick access to quality spare parts when needed.

7. Utilize Technology

- Monitoring Systems: Consider investing in monitoring systems that provide real-time data on pump performance. This data can help in making informed decisions regarding maintenance and parts replacement.

- Predictive Maintenance: Use predictive maintenance technologies to anticipate when parts will require replacement based on wear patterns and usage statistics.

Conclusion

Maximizing the benefits of progressive cavity spare parts involves a combination of selecting high-quality components, regular maintenance, training staff, and utilizing technology. By following these strategies, you can enhance the performance and longevity of your progressive cavity pumps, leading to increased operational efficiency and reduced costs. Remember, investing time and resources into proper care of spare parts will pay off in the long run with reliable and efficient pump operation.