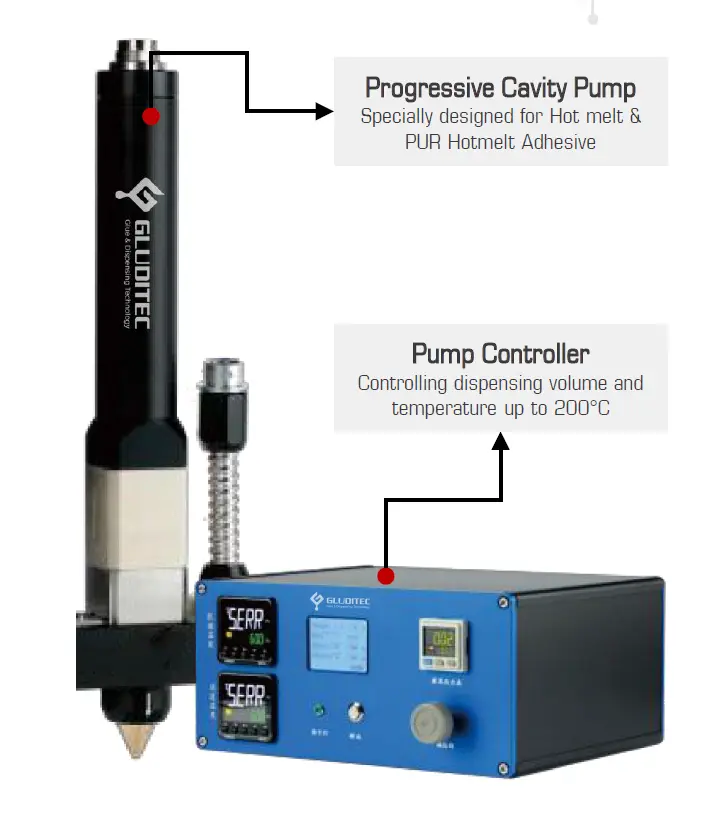

progressive cavity adhesives and liquids pump

Enhancing Fluid Transfer Efficiency with Progressive Cavity Adhesives and Liquids Pump

The utilization of progressive cavity pumps for handling adhesives and liquids has revolutionized fluid transfer processes across various industries. These pumps, known for their precision and reliability, excel in managing fluids with diverse viscosities and compositions. Let’s delve into the capabilities and benefits of progressive cavity adhesives and liquids pumps in optimizing fluid transfer efficiency.

Progressive Cavity Adhesives and Liquids Pump: A Versatile Solution

Progressive cavity pumps are engineered to deliver exceptional performance when it comes to transferring adhesives and liquids. Their positive displacement mechanism ensures a smooth and consistent flow, making them ideal for applications that demand precision and control over fluid transfer. From high-viscosity adhesives to delicate liquids, these pumps handle a wide range of substances with ease and accuracy.

Efficient Adhesive Handling

Viscosity Flexibility: Progressive cavity pumps can effortlessly manage adhesives of varying viscosities, maintaining a steady flow rate regardless of the adhesive’s thickness.

Gentle Operation: The low shear nature of these pumps prevents damage to adhesive components, preserving the integrity of the material throughout the transfer process.

Pulsation-Free Flow: The positive displacement design of progressive cavity pumps eliminates pulsations, ensuring a seamless and controlled flow crucial for precise adhesive application.

Optimal Liquid Transfer Applications

Chemical Processing Excellence: In chemical processing industries, progressive cavity pumps shine in transferring liquids such as solvents, resins, and polymers accurately and efficiently.

Food Industry Compliance: These pumps are indispensable in the food sector for transferring liquid ingredients, sauces, and syrups without altering their composition or quality.

Wastewater Treatment Support: Progressive cavity pumps play a vital role in wastewater treatment processes, facilitating the transfer of liquids including sludge and dewatering solutions with reliability.

Key Features for Adhesives and Liquid Handling

Material Compatibility: Available in various materials like stainless steel and elastomers, progressive cavity pumps ensure compatibility with a wide range of fluids, including corrosive chemicals and adhesives.

Solids Management: The pumps’ ability to handle liquids with suspended solids or abrasive particles makes them suitable for demanding applications in industries such as mining and construction.

Self-Priming Capability: The self-priming feature of progressive cavity pumps enhances efficiency, especially in scenarios where the pump is positioned above the fluid level.

Unlocking Benefits with Progressive Cavity Pumps

Consistent Performance: These pumps provide a reliable and steady flow rate, enabling precise dosing and application of adhesives and liquids in various processes.

Ease of Maintenance: With simple maintenance requirements and fewer moving parts, progressive cavity pumps offer a cost-effective and dependable solution for fluid transfer operations.

Versatility in Application: The adaptability of progressive cavity pumps to handle a broad spectrum of fluids makes them a versatile choice for diverse industrial applications.

In conclusion, the integration of progressive cavity adhesives and liquids pumps has significantly enhanced fluid transfer efficiency across industries. Their ability to handle adhesives, liquids, and even challenging substances with finesse and precision underscores their importance in ensuring smooth and reliable fluid transfer processes. By leveraging the advanced features and benefits of progressive cavity pumps, businesses can elevate their operational efficiency and productivity while maintaining the quality and integrity of transferred fluids.