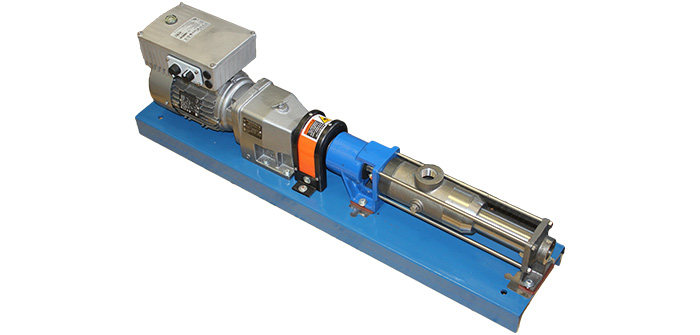

progressive cavity dosing pumps

key words:progressive cavity metering pumps,progressive cavity metering pump,progressive cavity dosing pump

How it works

The Progressive Cavity Pump consists of a rotor and stator that create sealed cavities for the material to flow through. As the rotor revolves inside the stator, the material is rotated through the sealed cavities in a consistent, continuous flow allowing the material to be pushed rather than squeezed, therefore not damaging the fillers or shearing the media needed for your application.

Unmatched Performance

- High accuracy

- High repeatability

- Continuous dosing

- Speed proportional

- Low pulsation and shear

- Well-suited for abrasive materials

- Available in several volumes for application flexibility

Material Compatibility

- Thermal Interface Materials (TIMs)

- Silicones

- Epoxy resin adhesives

- Solder paste

- Flux

- Grease

- Epoxies

- Polyurethanes