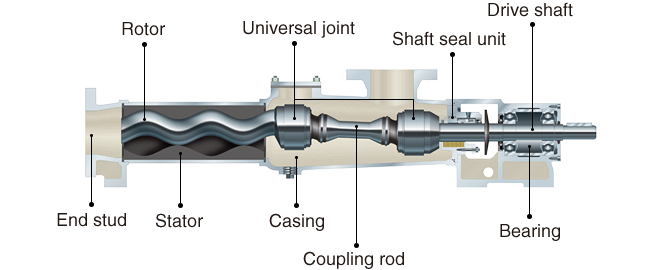

progressive cavity pump diagram

How do progressive cavity pumps work?

Progressive cavity pumps, otherwise referred to as a helical rotor pump, eccentric screw pump or mono pump, are part of the positive displacement family. Positive displacement pumps are characterised by an operation that moves fluid by trapping a fixed volume and forcing that trapped fluid into the discharge pipe.

The progressing cavity working principle in particular consists of a spiralled helical rotor (like a cork screw, hence their names eccentric screw pump) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.

Design benefits

Viscous & abrasive fluids – The progressive cavity pump is often seen as a solution when many other types fail thanks to their ability to handle difficult fluids. Its low internal velocity design means that viscous fluids and those containing solids can be handled effectively e.g. sewage, slurries, waste water and food waste. In addition, the stator has some flexibility reducing the wear particles cause as the come into contact. This is this reason why a mono pump is often selected over centrifugal pumps; a design most suited to water or fluids with a similar thickness, or vane and gear pumps that would simply clog with the presence of solids due to their close tolerances.

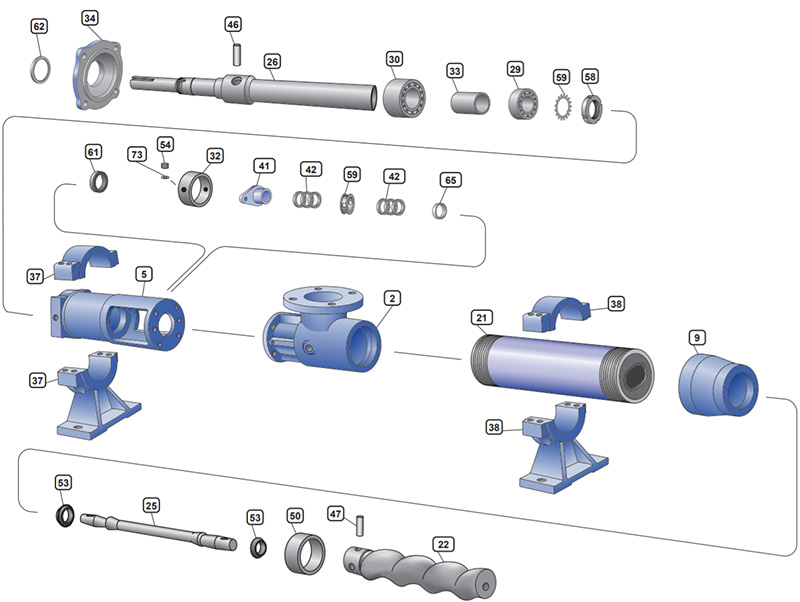

progressive cavity pump diagram

Smooth, low pulsating flow – As the fluid progresses through the overlapping cavities steadily at a predictable rate, the progressive cavity design benefits from low pulsation pumping. This smooth operation means that in dosing applications, extremely accurate metering can be carried out. Less pulsations in the flow of fluid also limits the amount of stress the other components in the installation are put under.

Constant flow – As a progressive cavity pump is able to produce the same flow rate regardless of the viscosity of the medium being pumped, they are an ideal solution for when a constant flow is required but the thickness of the fluid may be variable.

High pressures – High pressures can be achieved with eccentric screw pumps, ensuring that even difficult to pump fluids can be pump over considerable distances.