progressive cavity pumps parts

In modern industry and water treatment, progressive cavity pumps are favored for their excellent performance and wide range of applications. Designed specifically for conveying viscous, solid-containing fluids, this pump is suitable for a variety of industries such as petroleum, chemical, food and wastewater treatment. To ensure its efficient operation, it is important to understand and maintain progressive cavity pumps parts.

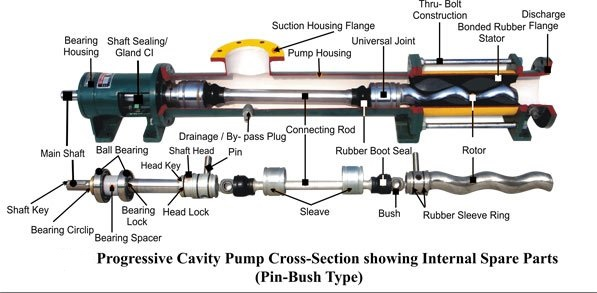

Parts Composition

The main components of a progressive cavity pump include the rotor, stator, drive unit and sealing system. The rotor and stator are the heart of the pump, and their design determines the efficiency and durability of the pump. The rotor is usually made of high-strength materials to ensure stability under high loads. The stator provides a closed channel for the fluid to ensure smooth flow of the fluid.

Performance and Reliability

Using high-quality progressive cavity pumps parts is essential for the performance and reliability of the pump. The quality of these parts directly affects the pump’s delivery capacity and operating life. Choosing original or high-quality replacements can effectively reduce the failure rate and improve work efficiency. In addition, regular inspection and replacement of worn parts can avoid unexpected downtime of equipment at critical moments and ensure the smooth progress of the production process.

Importance of Maintenance

Regular maintenance is another key factor to ensure the long-term and effective operation of progressive cavity pumps. During the maintenance process, it is particularly important to pay attention to these key parts. Check the wear of the rotor and stator, as well as the integrity of the sealing system, so that problems can be discovered and repaired or replaced in time.

Suppliers usually provide detailed data and technical support for replacement parts to help users quickly find suitable solutions when failures occur. This support not only improves the efficiency of maintenance work, but also ensures the optimal operation of progressive cavity pumps, thereby improving the stability of the entire production line.

Conclusion

In general, progressive cavity pumps parts play a vital role in the operation of progressive cavity pumps. Understanding and selecting high-quality parts is essential to improve the performance of the pump and extend the life of the equipment. Through regular maintenance and timely replacement of damaged parts, enterprises can achieve continuous and efficient production, reduce the risk of failure, and ensure steady progress in the competitive market. With the continuous advancement of technology, paying attention to the quality and maintenance of parts will become an important factor in promoting industrial development.