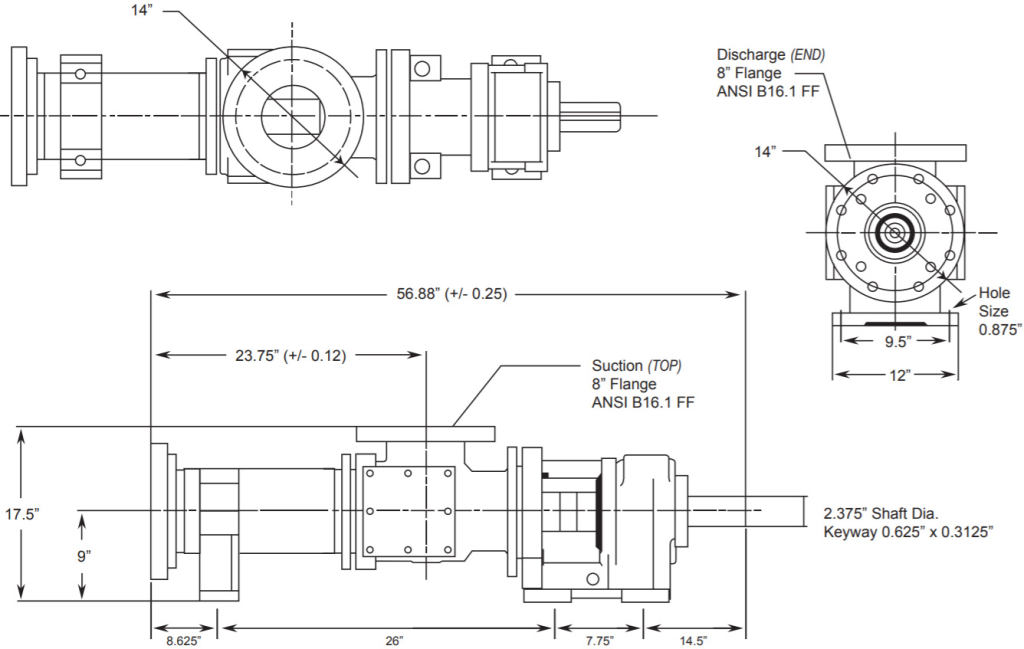

progressive cavity pump drawing

Progressive Cavity Pump: Exploring Its Design through a Technical Drawing

A progressive cavity pump, also known as a helical rotor pump, is a positive displacement pump that operates on the principle of a helical rotor turning within a helical stator to move fluid through cavities from the suction side to the discharge side. Let’s delve into the design of a progressive cavity pump through a detailed technical drawing:

Progressive Cavity Pump Drawing:

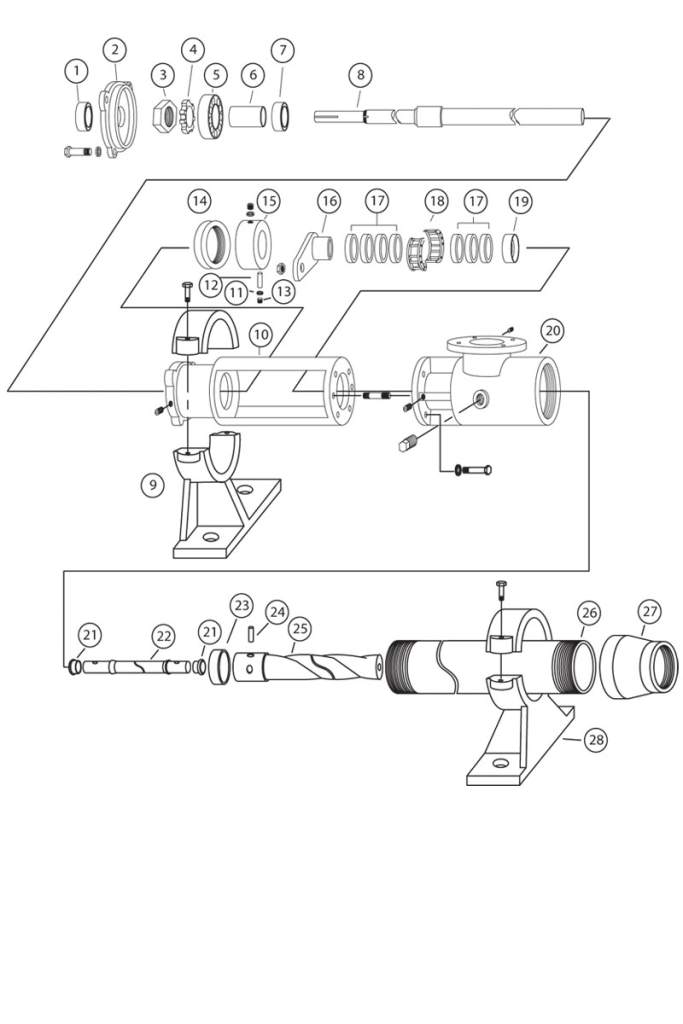

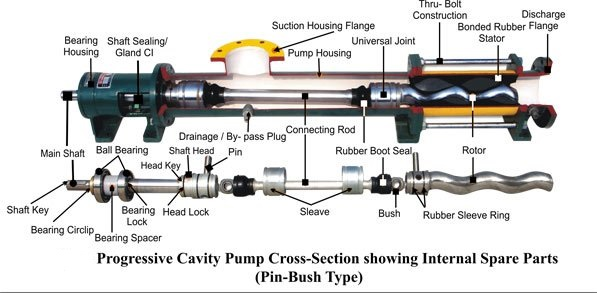

Rotor (Screw):

The rotor is the central rotating element of the pump, typically made of high-quality alloy steel for durability.

Its helical shape plays a crucial role in moving the fluid axially through the pump.

Stator (Casing):

Surrounding the rotor is the stator, usually made of elastomeric material with a helical internal shape that matches the rotor.

The stator remains stationary and forms the cavities with the rotor for fluid transfer.

Inlet and Outlet Ports:

The pump features clearly marked inlet and outlet ports for fluid entry and discharge.

The inlet port allows fluid to enter the pump, while the outlet port releases the pumped fluid.

Drive Shaft:

Connected to the rotor, the drive shaft transmits rotational motion from the motor to the rotor.

It is a critical component that ensures the rotor rotates smoothly within the stator.

Bearings and Seals:

The pump includes bearings to support the rotor and prevent excessive wear during operation.

Seals are vital for maintaining a tight seal between the rotor and stator, preventing leaks and ensuring efficiency.

Housing:

The pump housing encases the rotor, stator, and other internal components, providing structural support and protection.

It is typically constructed from durable materials such as cast iron or stainless steel.

Key Components and Operation:

As the rotor rotates within the stator, cavities are formed and progress along the helical path, displacing fluid from the suction side to the discharge side.

The progressive cavity pump’s positive displacement design ensures a consistent and pulsation-free flow, making it suitable for handling shear-sensitive fluids and viscous materials.

Applications and Benefits:

Progressive cavity pumps find applications in industries such as wastewater treatment, food processing, oil and gas, and chemical processing.

Their gentle handling, self-priming capabilities, and ability to handle solids make them versatile and efficient solutions for various fluid transfer tasks.

In conclusion, the intricate design of a progressive cavity pump, as illustrated in the technical drawing, showcases the synergy between its components to achieve reliable and effective fluid handling. Understanding the inner workings of this pump can help in optimizing its performance and maintenance for a wide range of industrial applications.