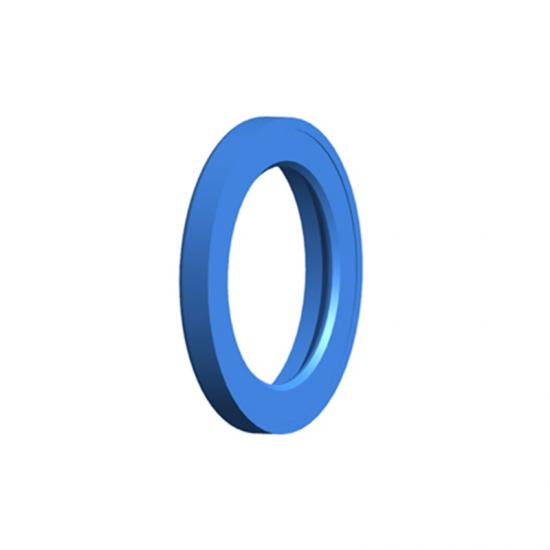

fracking pump seals

Fracking, or hydraulic fracturing, has transformed the oil and gas industry, enabling the extraction of hydrocarbons from previously unreachable reserves. A critical component of this process is the fracking pump, which requires reliable and durable seals to ensure efficiency and safety. Fracking pump seals play a pivotal role in preventing leaks and maintaining system integrity, making them essential for successful operations.

Fracking involves injecting high-pressure fluid into rock formations to create fractures, allowing oil and gas to flow more freely. The pumps used in this process operate under extreme conditions, including high pressure and abrasive fluids. As such, the seals in these pumps must withstand considerable stress and prevent any leakage from occurring. If a seal fails, it can lead to significant operational challenges, including fluid leaks, which not only compromise efficiency but also pose environmental risks.

One of the key factors in the selection of fracking pump seals is their material composition. Seals must be made from materials that resist wear, chemical corrosion, and temperature fluctuations. Common materials include elastomers and advanced composites specifically designed for high-performance applications in fracking. Investing in high-quality seals minimizes the risk of pump failure and extends the lifespan of the equipment.

Additionally, regular maintenance and inspection of fracking pump seals are vital. Operators must monitor the condition of seals to identify signs of wear and prevent catastrophic failures. Implementing a proactive maintenance schedule ensures that any potential issues are addressed before they escalate, safeguarding both operator safety and environmental integrity.

The market for fracking pump seals has seen significant growth, driven by the increasing demand for efficient oil and gas extraction methods. Manufacturers are constantly innovating, developing seals that can handle the specific challenges posed by different fracking environments. As technology evolves, the performance of fracking pump seals continues to improve, allowing for safer and more efficient operations.

In conclusion, fracking pump seals are crucial for the success of hydraulic fracturing operations. Their ability to prevent leaks and maintain pressure integrity is fundamental to the safety and efficiency of the process. By selecting quality seals and following best maintenance practices, operators can ensure the continued viability of their fracking operations, contributing to the overall progress of the energy sector.